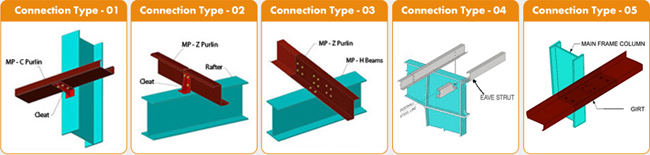

These purlins are most unique cold roll formed sections used to fix roof and side claddings. The advanatage of using these women in pharmacy purlins are unlimited depth and thickness option gives the designer the required freedom to design most economical purlin.

Minimum yield strength of these purlins will be 320 Mpa which enables designer to design light weight purlin.

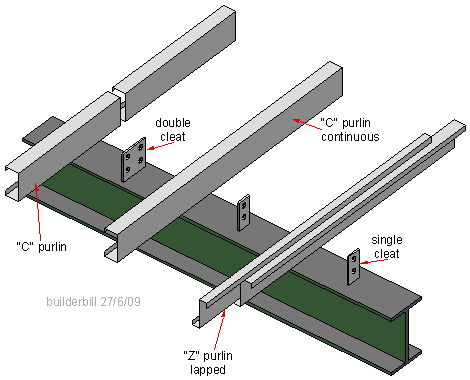

“Z”purlins can be supplied from 100 mm depth to 300 mm depth and thickness of 1 mm to 3 mm.

“C”purlins can be supplied from 100 mm depth to 300 mm depth and thickness 1 mm to 3 mm

Z and C Purlin / Section

- IS 513/IS 277/IS 10748/IS 1079

- G240 MPA/G340 MPA/G550 MPA, Z 120 GSM/Z 275 GSM & Z 180 GSM

- G indicates Yield Strength in MPA & Z indicates Coating Mass in G/M2

Steel Grade

- ALFAA Zed & CEE Purlins with punching

Thickness

- Sleeves

- Cleats

- Sag rods

HR Purlins

- Yield Strength – 240 MPA

- Option – Redoxide Primer Coating

GI Purlins

- Coating Mass – 120 GSM / 180 GSM / 275 GSM

- Yield Strength – 240 MPA / 340 MPA / 550 MPA

Advantages

Economy

- Savings in steel consumption upto 50% and savings in cost upto 30%

- Savings of transportation & handling, erection and fabrication costs

- No wastages, No surplus left-overs, since sections are supplied in exact required lengths

Design

- High strength, section versatility & wide range of choice

- Having their shear centre within the section, less liable to twist

Structure

- Sleeve system to exploit continuity concept for larger spans

- Empirical design rules apply, hence no design problems

- Excellent surface finish

- Less weight per unit length compared to conventional section without sacrificing the required structural efficiency

- Conforming to the requirements of IS-801, IS-811

Practical Advantages

- Ability to rotate 180 degrees and fit together

- A full range of fixing accessories is supplied. Therefore no extra material needs be procured

- Sections supplied are pre-painted hence prevents corrosion and promotes long life

- Sections are pre-engineered, pre-punched and with complete accessories. No further fabrication required . Considerable savings in erection costs and time.

| TECHNICAL SPECIFICATION OF Z AND C | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| purlin DEPTH D | Thickness(t) | Mass(Kg/M) | ZED PURLIN | CEE PUTLIN | |||||

| F | L | F | L | ||||||

| 160 | 2.00 | 4.82 | 60 | 20 | 60 | 20 | |||

| 160 | 2.30 | 5.54 | 60 | 20 | 60 | 20 | |||

| 160 | 2.55 | 6.15 | 60 | 20 | 60 | 20 | |||

| 200 | 2.00 | 5.44 | 60 | 20 | 60 | 20 | |||

| 200 | 2.55 | 6.95 | 60 | 20 | 60 | 20 | |||

| 230 | 2.00 | 5.92 | 60 | 20 | 60 | 20 | |||

| 230 | 2.30 | 6.87 | 60 | 20 | 60 | 20 | |||

| 230 | 2.55 | 7.55 | 60 | 20 | 60 | 20 | |||

| 250 | 2.00 | 6.23 | 60 | 20 | 60 | 20 | |||

| 250 | 2.30 | 7.17 | 60 | 20 | 60 | 20 | |||

| 250 | 2.55 | 7.95 | 60 | 20 | 60 | 20 | |||